Seth Ackerman

Flight Test Engineer

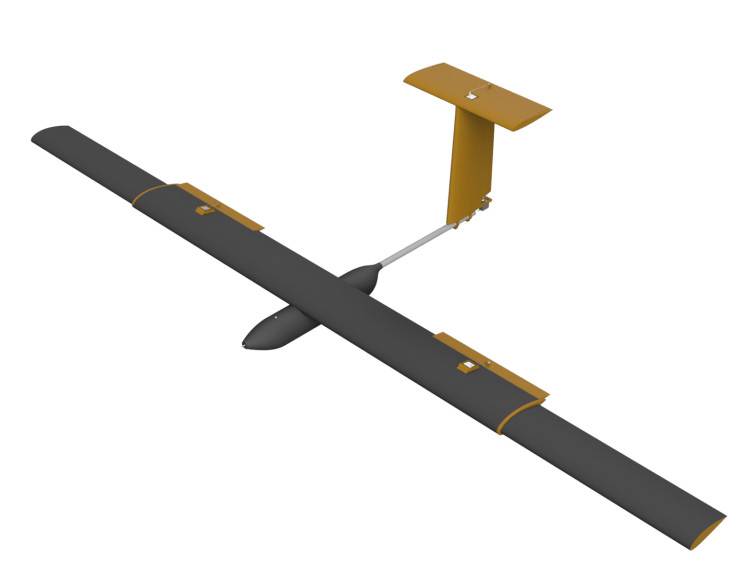

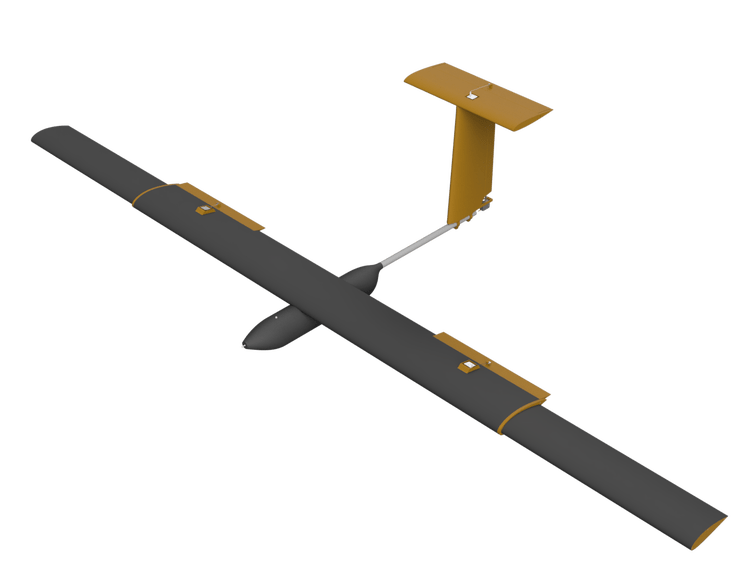

Morphing Wing

This is a senior design project at Florida Institute of Technology. In this project, I created the CAD model and worked with fellow team members to appropriately size aerodynamic surfaces and securely house all of the electronics. The moving wings nest inside the static wing and telescope out symmetrically. The wingspan can go from 2 meters when retracted to 3.5 meters when fully extended.

Odyssey of the Mind

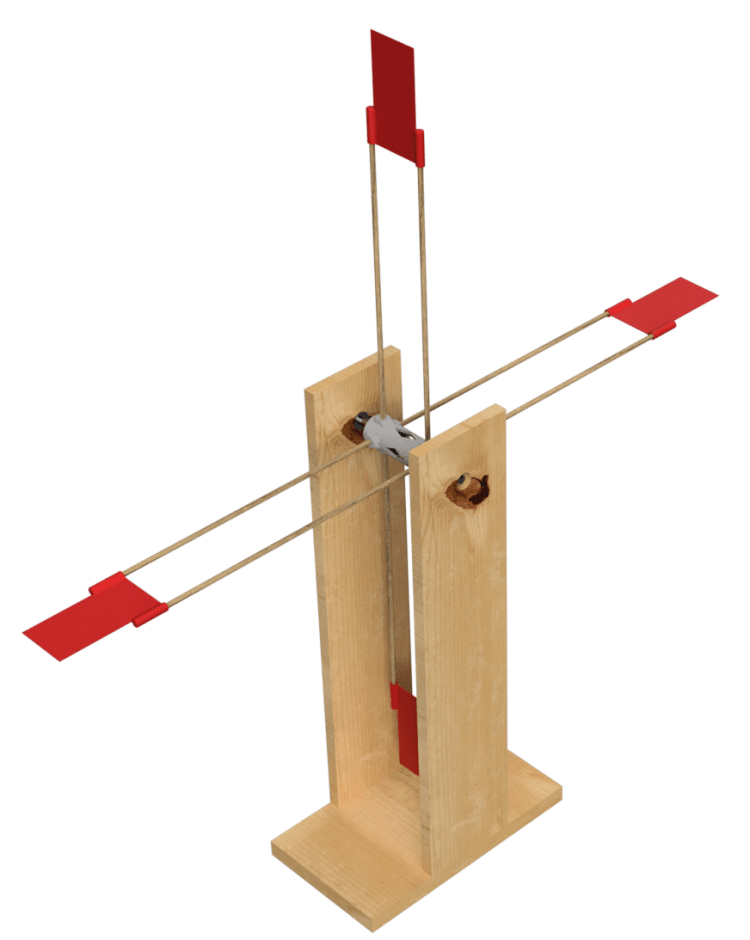

I volunteer to create the Florida booth at the Odyssey of the Mind world competition creativity fair. This year I have created a game where players shoot puffs of air at spinning and moving targets to gain points. The primary targets will be ‘propellers’ that spin when shot with a puff of air. These propellers are entirely 3D printed and high modularity allows for quick repairs.

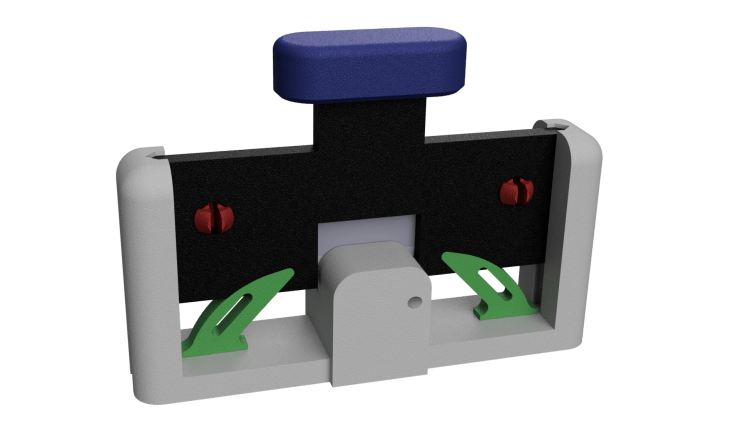

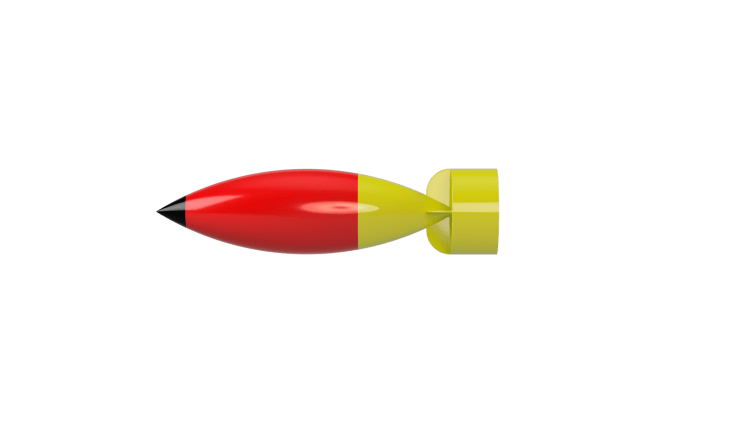

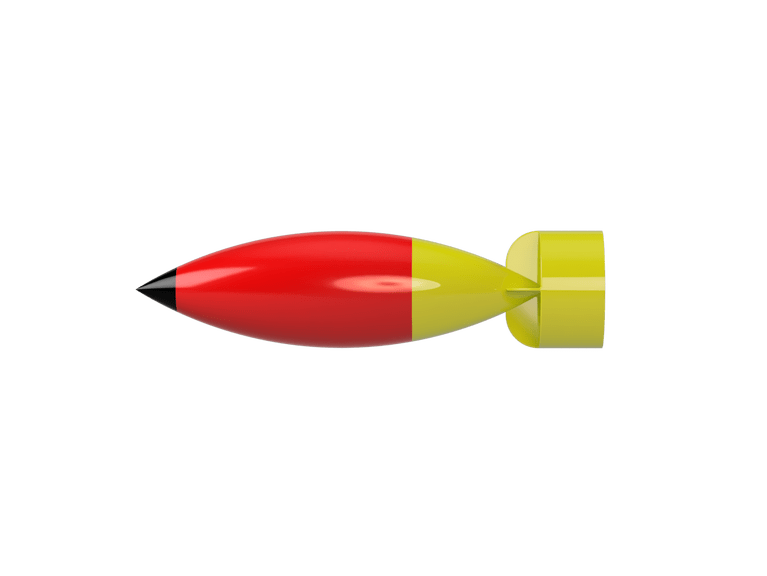

Aerodynamic Sensor Platform

The Aerodynamic Sensor Platform (ASP) was a one-meter shell that housed a smartphone-based sensor inside a 3D-printed shell. The ASP was designed to be dropped out of a small General Aviation plane into the ocean, where a boat would retrieve it. Simulations showed that the device could exceed 200 mph during its freefall. A suitable plane, boat, and chase plane were scheduled to assist with the experiment, however two days before the experiment, new information was found that showed a significant risk of collision with the release aircraft. Due to the possibility of the ASP rising up and striking the release aircraft, it was never dropped.

Experience

Education

Bachelor of Science in Aerospace Engineering

Florida Institute of Technology, Melbourne, FL

May 2021

Skills

OnShape, MATLAB, IADS, Excel, Fusion 360, SolidWorks, AutoCAD, Blender, FFF 3D Printing, SLA 3D Printing, PrusaSlicer, Cura, ChituBox, Microsoft Office, G Suite

Professional Experience

Lockheed Martin Sikorsky

Stratford, CT

Jan 2023 – Current

Noise, Vibration, and Harshness Engineer

- Developed applications in MATLAB to automate data processing and visualization.

- Authored detailed maintenance procedures to increase aircraft availability and reduce maintenance demands

- Conducted in-flight data acquisition during test flight activities

- Managed the procurement, operation, and maintenance of multiple FFF 3D printers

- Conducted flight testing and authored key sections of test reports for aircraft diagnostic systems

- Engaged in research leading the CAD modeling and 3D printing of an innovative mechanism

- Designed and additively manufactured mechanical assemblies

- Performed Trim Tab bending to support aircraft maintenance

- Directed maintenance actions to support flight operations

- Collaborated with customer maintainers in the field to observe product usage and identify necessary changes

- Completed trainings and clearances required for on-aircraft support including Ditching & Water survival training, Class III FAA Medical, and aircraft familiarization

Lockheed Martin Sikorsky

Patuxent River, MD

June 2021 – Jan 2023

Flight Test Engineer

- Monitored real-time telemetry to ensure Aircraft safety during Envelope Expansion testing using IADs Real Time

- Reviewed and edited data to ensure accuracy and validity

- Verified on-aircraft instrumentation

- Responsible for tracking accrued damage on aircraft components on multiple aircraft

- Automated component tracking for damage calculations using MATLAB

- Created a set of custom functions to return data from servers into Excel

- Maintained legacy code

- Created and maintained data processing files

- Reviewed flight cards for areas of concern within my cognizance

- Created flight cards according to test plans

- Operated in accordance with test plans and joint operating procedures

- Worked in an Integrated Test Team (ITT) with NavAir customers

Jaycon Systems

Melbourne, FL

April 2019 – June 2021

Mechanical Engineer Trainee

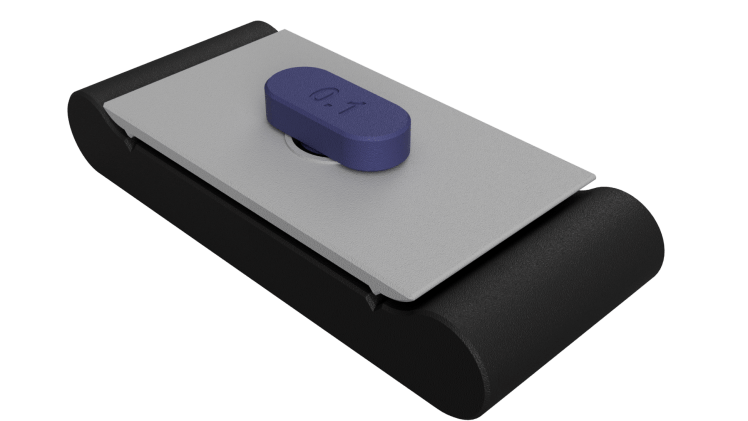

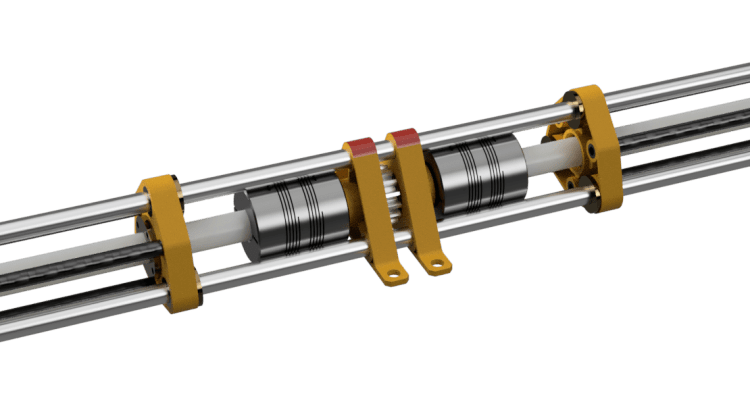

- Designed For Manufacturing (DFM) parts to make designs appropriate for injection molding, FFF 3D printing, resin 3D printing, machining, welding, or casting

- Created designs in Fusion 360 and SolidWorks ready for prototyping and manufacturing

- Rapidly iterated designs to conform to changing requirements

- Created engineering drawings for product verification and quality control

- Produced clear manufacturing, assembly, and testing instructions for use in all languages and cultures

- Created Quality Assurance procedures and methods utilizing a CMM

- Utilized 6 DOF robotics to simplify or improve packaging, testing, and other tasks

- Assisted the Lead Mechanical Engineer by creating subcomponents in larger assemblies

- Worked with Prototyping Technicians to better understand and design for current in-house production capabilities

- Worked with Electrical Engineers to create PCB programming jigs, assembly jigs, and protective casings

- Maintained and upgraded 3D printers to be more cost-effective, reliable, and accurate

Halo Technologies,

West Palm Beach, FL

Aug 2016 – Apr 2019

Engineering Contractor

Engineering Intern

- Consulted with clients to help solidify invention ideas, and discuss appropriate design methods, manufacturing methods, and materials

- Used simulations in programs such as Fusion 360 to determine heat dissipation, impact forces, stresses, and deflection

- Reproduced parts by carefully measuring existing components, extrapolating angles and dimensions, modeling in Fusion 360, slicing the model in simplified 3D or Cura, and 3D printing the parts

- Created drawings and animations of 3D models in Fusion 360 and AutoCAD for use with other engineering companies and investors

- Used Creaform Go! 3D scanner and VXmodel to create a virtual copy of a physical object, as well as to verify dimensions of safety-critical objects

- Created Filament Inventory Tracking System, which used QR codes to track and report filament use

- Diagnosed and fixed FFF 3D printers by systematic inspection and disassembly, and fixing or replacing broken or misaligned parts

- Researched, documented, and utilized 3D printed composite materials such as carbon fiber ABS, ceramic composites, steel PLA, and copper ABS

- Created a 3D Scanning booth for rapid and consistent scanning of people

Honors and Certifications

- IADs Generic Intermediate and Advanced Structures training

- Survival Systems ditching & water survival training

- Autodesk Fusion 360 Certified User

- Eagle Scout

Other Experience

Mechanical Mentor for FRC team 836 RoboBees — Jun 2021 – Jan 2023

Mechanical Mentor for FRC team 8085 Mojo — Jan 2023 – Current

Morphing Wing,

Senior Design Project

Melbourne, FL

Jan 2020 – May 2021

Structures Lead

- Created CAD design of a telescoping wing drone.

- Created the project and subsystem requirements as part of a team.

- Created animated video to show different components of the vehicle and how they work – https://youtu.be/UnDsBbMGFDg

- Prototyped key features and found solutions to unexpected problems.

- Simulated expected loading in Fusion 360 to provide early and continuous feedback on the structural integrity of the design

Creativity Fest,

Odyssey of the Mind (volunteer)

2016 – current

Booth Designer

- Created carnival-style booths from scratch out of plywood, PVC, fabric, etc.

- Designed and 3D printed an Air cannon that will spin when hit by an ‘air cannon’.

Get In Touch

setha247@gmail.com