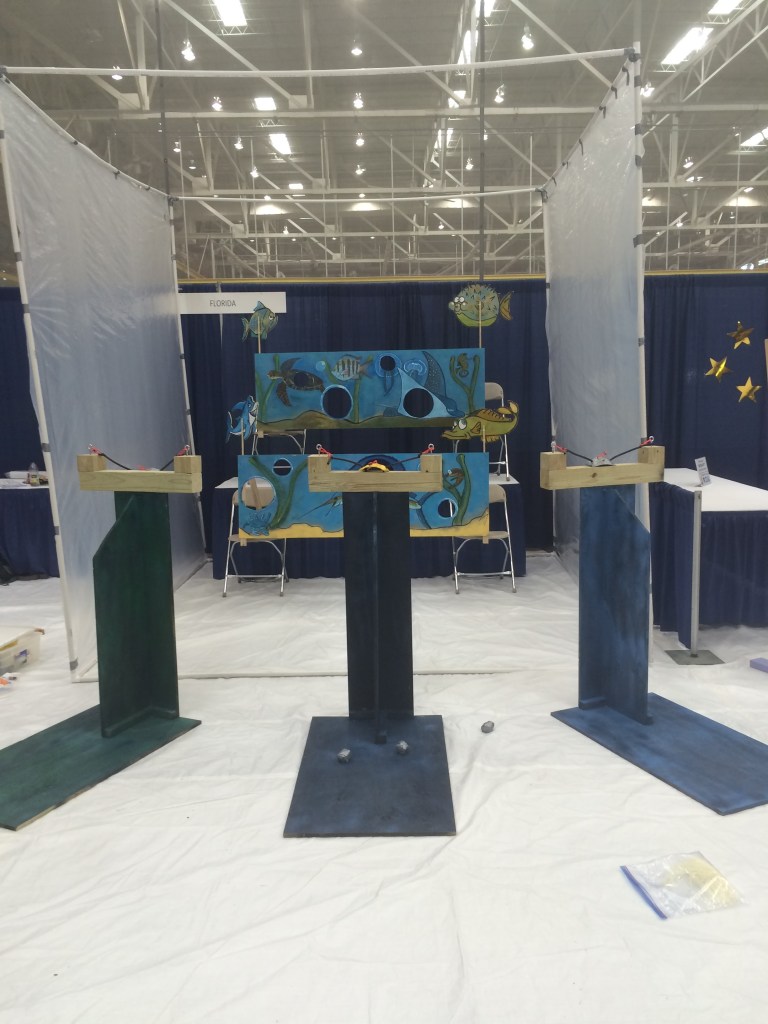

Purpose & Background

The purpose of this project was to create a carnival booth type game to be used by a non-profit organization called Odyssey of the Mind. Odyssey of the Mind is an international creative problem-solving competition. At the world competition, there is a ‘Creativity Fest’, where every state/country is represented by a carnival-style game. The Florida Odyssey of the Mind Association has asked me to create a new booth for the creativity fest every year since 2016. Along with my dad Ed Ackerman, I have made new games each year and won several awards.

For the 2020 Creativity Fest, (deferred to 2021 due to the pandemic) the Florida theme was History of Flight, and so we decided to have a carnival game powered by air. The power will come from ‘air cannons’, which use a bungee-powered diaphragm to push a puff of air. These air puffs will be used to power different targets arranged in front of the players.

Execution

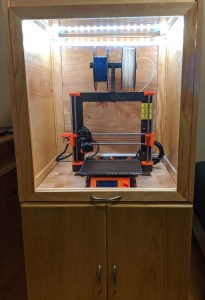

This project had to be completed for as low a cost as possible, while still providing a unique experience to the users. Fused Deposition Modeling (FDM) 3D printing was chosen because it was easy to access, low cost, and simple to use. It was desired to print as many of the parts as possible in order to further reduce costs, and this choice impacted the design of the project. While there will be several different targets in the game, the most complex target will be a propeller. The propeller will have to spin when hit with puffs of air.

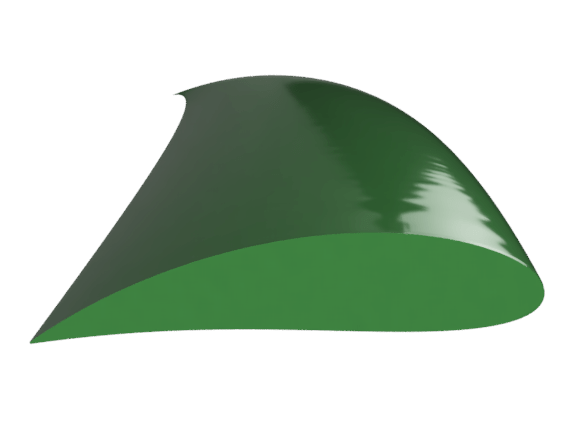

Airfoil

A thick airfoil was required for several reasons, but the primary concern was the ease of manufacturing. Subscale parts allow for faster and cheaper prototyping, and from prior experience, it was found that many airfoils are too thin to 3D print in small designs. A NACA 7520 airfoil was chosen, as its thicker profile allowed for easier printing at both full-scale and subscale sizes, while still maintaining the distinctive airfoil appearance. The final chord size of the airfoil was determined experimentally by printing out samples and testing until the propeller spun well when hit with the air cannon. If the chord of the airfoil was too small the propeller would not spin, and if the chord was too large it would waste machine time and material.

Screws

While for larger-scale manufacturing it would be cheaper to use premade off-the-shelf screws, so few were needed for this project that the screws were 3D printed as well. This design choice drove several parameters, as 3D-printed plastic screws need to be thicker to maintain strength. The added thickness of the screws increased the size of the spinner hub, but the tradeoff was considered to be worthwhile.

Bearing

The bearings for this project were thoroughly researched. Three main types of ball bearings were considered, a 3D-printed bearing, a ceramic bearing, and a steel bearing. An existing design for a suitable 3D printed bearing was not found, and after reviewing the existing but unsuitable 3D printed bearings, it was decided not to create a new custom design due to the expected resistance. Ceramic bearings were considered due to their low resistance, but due to the cost of these bearings, steel bearings were attempted first. A simple and cheap steel bearing was chosen, and after the grease was removed and replaced with oil, the cheap steel bearing worked perfectly, with no need to upgrade to ceramic.